Round Bar

Alloy Alliance stands as a premier global supplier and exporter of high-quality round bars, providing comprehensive steel solutions to industries worldwide with exceptional precision and reliability. Our extensive inventory encompasses hot rolled round bars, cold drawn round bars, bright bars, and precision ground bars, each manufactured to meet stringent quality standards and diverse industrial requirements. We serve a wide array of sectors including automotive manufacturing, aerospace engineering, construction, machinery manufacturing, oil and gas, marine engineering, and general fabrication, where round bars form the backbone of critical components and structural applications.

Our round bar portfolio features an impressive range of materials including carbon steel grades, stainless steel variants such as 304, 316, 316L, 321, 347, 410, and 420, alloy steels, tool steels, and specialized materials like duplex steel, super duplex steel, Inconel, Hastelloy, and titanium alloys. We offer round bars in compliance with international standards including ASTM, AISI, EN, DIN, JIS, and IS specifications, covering diameters from small precision bars to large diameter applications up to several inches. Our products are available in various surface finishes including black, pickled, polished, and centerless ground, ensuring optimal performance for specific machining and fabrication requirements.

Quality assurance forms the foundation of our operations, with every round bar undergoing comprehensive testing including tensile strength verification, hardness testing, chemical composition analysis, and dimensional accuracy checks to ensure compliance with international metallurgical standards. Our products come with complete material certification, mill test certificates, and traceability documentation, providing customers with confidence in material properties and performance consistency.

As experienced exporters, Alloy Alliance provides comprehensive support services including technical consultation, custom length cutting, heat treatment services, and efficient global logistics management. Our technical team works closely with clients to recommend appropriate grades, sizes, and specifications based on their specific application requirements, ensuring optimal machinability, strength characteristics, and cost-effectiveness across diverse manufacturing and construction projects worldwide.

Specifications

| Grade | Stainless Steel Round Bar |

|---|---|

| Stainless Steel Square bar size | 4 to 100mm |

| Stainless Steel Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Hot Rolled Steel Hex Bar size | 2-100mm A/F |

| Stainless Steel Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Stainless Steel Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hot Rolled Steel Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Stainless Steel Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Stainless Steel Section | 3.0 to 12.0mm thickness |

| Hot Rolled Steel Round bar size | Diameter: 3-~800mm |

| Stainless Steel Billet Size | 1/2" to 495mm Diameter |

| Stainless Steel Round Bar Standard Dimensions | Diameter / Height: Stainless Steel Rod and Bar Sizes : 0.5 inches / 0.625 inches / 0.75 inches / 0.875 inches / 1.0 inches / 1.125 inches / 1.25 inches / 1.375 inches / 1.5 inches / 1.75 inches / 2.0 inches / 2.25 inches / 2.5 inches / 2.75 inches / 3.0 inches / 3.25 inches / 3.5 inches / 3.75 inches / 4.0 inches / 4.25 inches / 4.5 inches / 5.0 inches / 5.25 inches / 5.5 inches / 6.0 inches / 7.0 inches / 8.0 inches / 9.0 inches. |

| Stainless Steel Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Stainless Steel Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Hot Rolled Steel Technique | Stainless Steel Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Stainless Steel Condition | Hardened & tempered, annealed |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Form | Stainless Steel Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square Bar, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Processing | Bar cutting to 650mm |

Different Types Of Round Bars

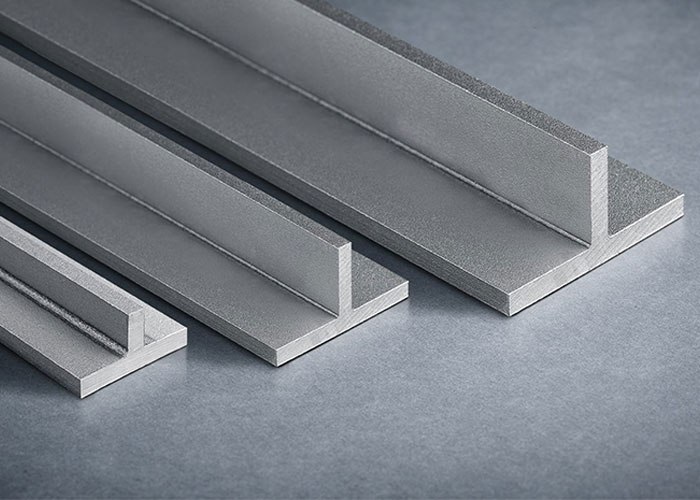

Flat Bars

Hexagonal Bars

Round Bars

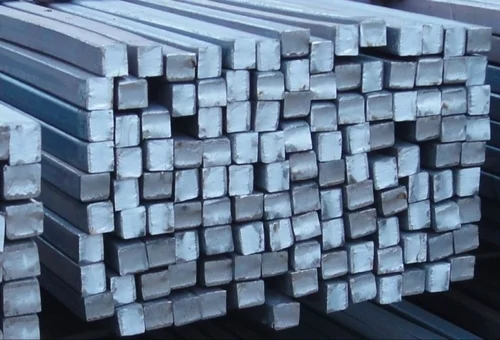

Square Bars

Tee Bars

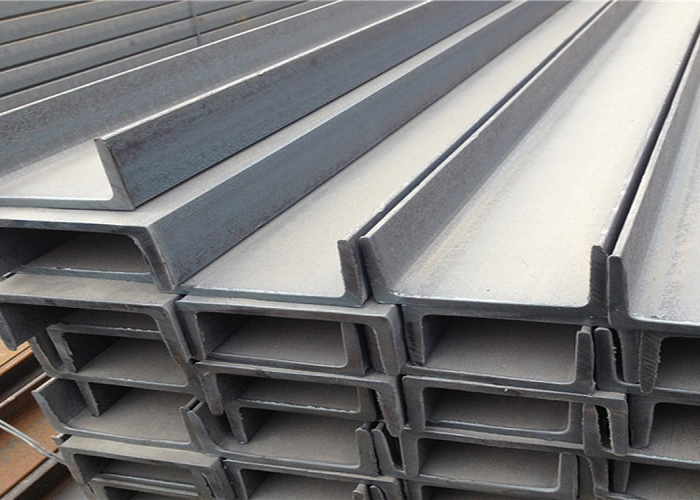

Channel Bars

Material & Grade

| Stainless Steel | ASTM / ASME SA 276, A479 TP 202, 304, 304L, 309S, 309H, 310S, 316, 316L, 316 TI, 317, 321, 347, 410, 420, 430, 431, 440A, B & C., 446 |

| Duplex Steel | 2205 (UNS No. S31803), 2507 (UNS No. S32750) |

| Super Duplex Steel | ASTM / ASME SA A582, A276, A564, ASTM A484, 484M UNS NO. S32750 / S32760 / S32950 |

| Carbon Steel | ASTM / ASME A 105, A53 GR B, A106GR B, API5L GRADE B, API 5L, GRX42 / 46 / 52 / 56 / 60 / 65 / 70, A333 GR 1/GR 3/GR 6, A/SA 672 GR 8C60/C70 etc.. |

| Alloy Steel | ASTM / ASME A 182 GR F 5, F 9, F 11, F 12, F 22, F 91. ASTM / ASME A 729 GR B 11 & B 22. |

| Nickel Alloy | ASTM / ASME SB 160 Nickel 200 (N02200), Nickel 201 (N02201), Nickel 205 (N02205) |

| Monel | ASTM / ASME SB 164 Monel 400 (N04400), Monel 500 (N05500) |

| Inconel | ASTM B408, AMS 5766, ISO 9723, ISO 9724, BS 3076NA15, BS 3075NA15, EN 10095, VdTüV 412 & 434 Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750, Incoloy 800, incoloy 825, Incoloy 925, Incoloy a-286 |

| Hastelloy | Hastelloy C22, Hastelloy C276, Hastelloy C4, Hastelloy B, Hastelloy C-2000 |

| Cupro Nickel Alloy | UNS No. C70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C10100, 10200, 10300, 10800, 12000, 12200, |

Equivalents of grade Round Bar

|

MATERIAL

|

ASTM | EQUIVALENT STANDARD | |||

| UNS | GRADE (TP) | DIN (EN) | AFNOR (NF) | JAPAN (JIS) | |

|

AUSTENTIC STAINLESS STEEL

|

S30400 | 304 | 1.4301 | Z6CN18-09 | SUS304 |

| S30403 | 304L | 1.4307 | Z2CN18-10 | SUS304L | |

| S31600 | 316 | 1.4401 | Z6CND17-11 | SUS316 | |

| S31603 | 316L | 1.4404 | Z2CND17-12 | SUS316L | |

| S31635 | 316Ti | 1.4571 | Z2CND17-12 | - | |

| S32100 | 321 | 1.4541 | Z6CNT18-10 | SUS321 | |

| S34700 | 347 | 1.455 | Z6CNNb18-10 | SUS347 | |

| S30409 | 304H | 1.4948 | Z6CN19-10 | SUS304H | |

| S31609 | 316H | 1.4919 | Z6CND17-12 | SUS316H | |

| S32109 | 321H | 1.4941 | Z10CND18-10 | SUS321H | |

| S31000 | 310 | - | - | SUS310 | |

| S31703 | 317L | 1.4438 | - | SUS317L | |

|

FERRITIC STAINLESS STEEL

|

S40500 | 405 | 1.4002 | Z6CAL13 | SUS405 |

| S41000 | 410 | 1.4006 | Z12C13 | SUS410 | |

| S43000 | 430 | 1.4016 | Z10C17 | SUS430 | |

|

DUPLEX STAINLESS STEEL

|

S32205 | 2205 | 1.4462 | Z2CND22-06 | - |

| S31803 | - | 1.4462 | Z2CND22-05 | - | |

Application Industries

Alloy Alliance supplies high-quality steel products to a range of industries, including petrochemical, chemical, pharmaceutical, oil and gas, nuclear, and offshore sectors. Our products are engineered to meet stringent industry standards, ensuring durability and reliability. With a robust stock and tailored solutions, Rajsheel Steel Industries supports critical infrastructure worldwide.

Petrochemical

Chemical

Pharmaceutical

Oil & Gas

Nuclear

Offshore

Packing Of Round Bars

Alloy Alliance carefully packages its products to ensure secure delivery and protection. Depending on client needs, items are packed in shrink-wrap, carton boxes, wooden pallets, wooden boxes, and wooden crates. Each packaging method is chosen for durability and safety, ensuring Alloy Alliance steel products arrive in excellent condition for various industries